Sustainability Report 2014

Sustainability

Report

Introduction

A clear and transparent account is given below of Termomecanica’s challenges and successes during 2014, focusing on corporate social responsibility, profitability and its organic growth strategy. Our Sustainability Report seeks to transmit the values that enable Termomecanica to transform not just non-ferrous metals but also people’s lives.

How We Prepared the Report

To prepare our Sustainability Report 2014, the Social Responsibility Division used as a benchmark the Ethos Indicators for Sustainable and Responsible Business and the IBASE (Brazilian Institute of Social and Economic Analysis) Table. In addition, to help asses the company’s performance and identify opportunities for improvement, different stakeholders were consulted and different approaches used:

► Confirmation of information on the company’s performance with management, when appropriate;

► Interviews with managers and staff in key areas;

► Formation of technical groups in different areas of the company to evaluate indicators, under the coordination of the Corporate Social Responsibility Division;

► A supplementary diagnostics report issued according to the third generation Ethos Indicators;

► Supporting documentation to confirm data.

As well as providing a thorough analysis, these methods helped reinforce Termomecanica’s relations with its staff and its partners, since the report highlights and disseminates the company’s sustainability efforts and the way it is managed.

Profile

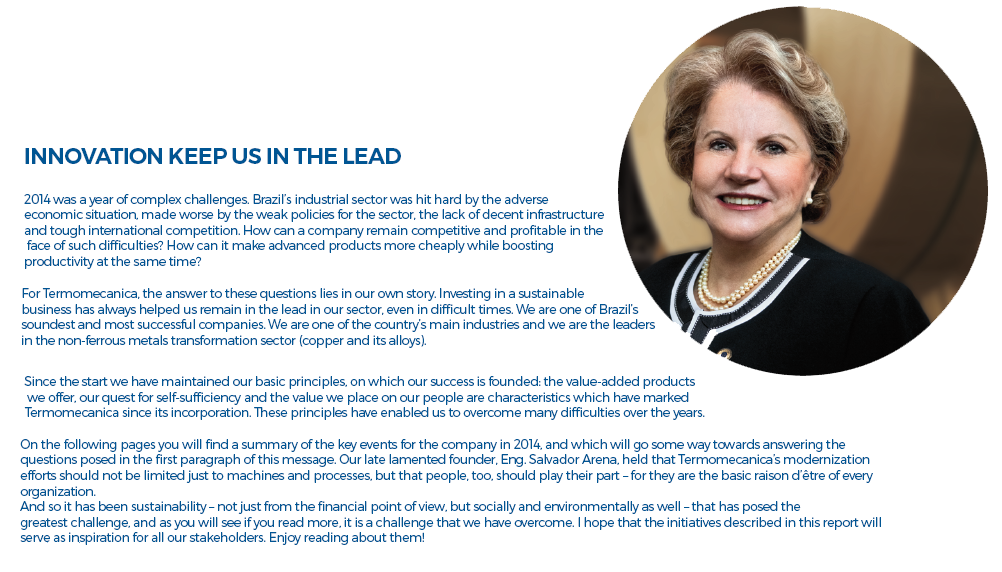

A Brazilian multinational company

Incorporated in 1942 by Eng. Salvador Arena, Termomecanica is one of Brazil’s biggest private industrial companies. Our

officers and managers are mainly based at the head office in São Bernardo do Campo, São Paulo. Two plants and one of the

distribution centers are also located in this city. The company has its other distribution center in Joinville, Santa Catarina,

and factories in Santiago do Chile and Tortuguitas, a district of Buenos Aires, Argentina, both of them acquired in

2011 when all the shares of Cembrass were purchased by companies belonging to the Termomecanica Group.

These two foreign units are the result of Termomecanica’s efforts to get closer to the sources of raw materials and

to boost its competitiveness internationally. Cembrass is a leader in the brass bars segment in the two countries,

and in 2014 it reinforced its position with new business promising good market potential in both Argentina and Chile.

Mission

To transform copper and other non-ferrous metals into products, services and solutions to meet our customers’ needs.

Vision

To be a leader in the domestic market with growing share of the global market.

Corporate Values

► Philanthropy;

► Social and environmental responsibility;

► Ethics and transparency;

► Skill and discipline;

► Appreciation and respect for people;

► Constant improvement;

► Care for our property;

► Pride in belonging to the organization.

Termomecanica

and the Salvador

Arena Foundation

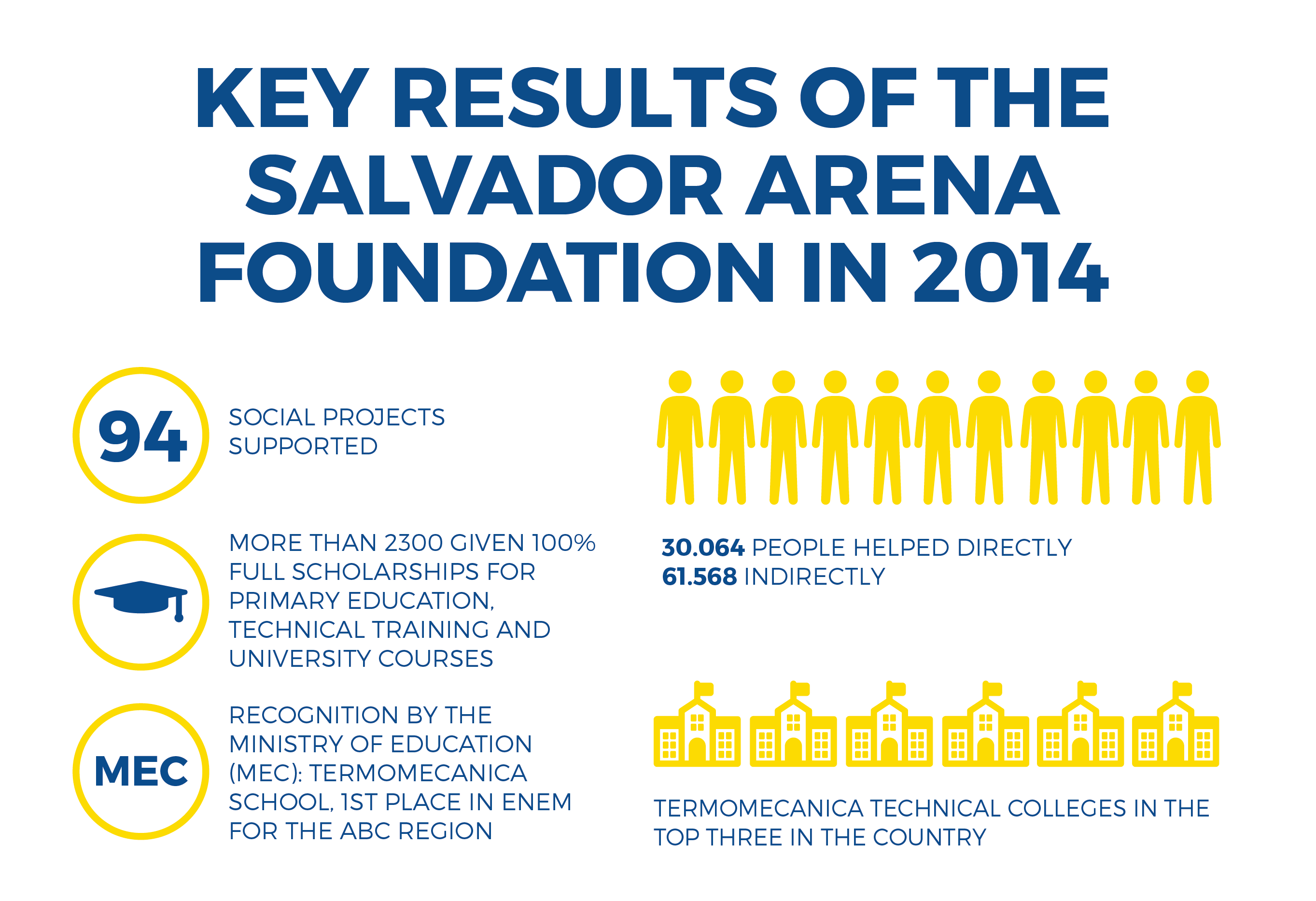

A closed-capital private company, Termomecanica is controlled by the Salvador Arena Foundation (FSA), a not-for-profit organization set up in 1964 by Eng. Salvador Arena, with the aim of giving meaning to the wealth generated by the company by supporting a number of social programs. Salvador Arena left no heirs, and his concern that his humanitarian ideals should be continued led him, in 1991, to bequeath all his fortune to the FSA, and to appoint a Council of Curators consisting of staff of the company to manage the institution.

When its founder died in 1998, the Salvador Arena Foundation became the sole controlling shareholder of Termomecanica, and the transformation of non-ferrous metals assumed a special significance, with the company’s profits helping to transform society as well. In the last ten years alone, FSA has invested some R$ 370 million in social benefits to 580 organizations, benefiting more than 425 thousand people directly and nearly a million indirectly. In the same period, more than 500 social managers and technicians were trained on management courses for Third Sector organizations arranged by the FSA. In partnership with Termomecanica, the Salvador Arena Foundation also assists the company’s own employees

Vision and strategy

The quest for more sustainable living

To remain at the head of its segment and to achieve a growing share of the global market, Termomecanica’s strategies focus on its key stakeholders – customers, suppliers, community, government, employees and families – stressing social and environmental factors that are decisive for the success of its business and to achieve a more sustainable way of life.

As well as monitoring the indicators for the ISO 14001 and OHSAS 18001 standards, so as to maintain the certificates it holds, Termomecanica gives priority to these issues in its decision-making, from the purchase of equipment to the refurbishment of its premises. Efficient use of natural resources and cutting environmental impact continue to be the company’s chief goals, as well as initiatives to improve occupational health and safety.

Governance and Management

Principles that endure

Termomecanica’s system of Corporate Governance, which was introduced in 2010 with the creation of a Board of Directors and its advisory committees, is constantly evolving. Our basic principles – transparency, equity, accountability and corporate responsibility – are bound up with the company’s philosophy – with what we believe in and share with our stakeholders. No effort has been spared to consolidate the system, even beyond what the law requires in the case of a private company. A good example of this is the work done in partnership with the Termomecanica Corporate University in line with the most important related concepts. More than four thousand people took part in 2014, 1158 of them studying at the Management school. Highlights include courses for senior management, focusing on Corporate Governance and succession planning, since one of our chief concerns is to ensure that our principles will endure.

Ethical conduct and behavior

Termomecanica believes that ethical business conduct is essential for its development as a citizen company. Accordingly it always observes the requirements of the law, irrespective of regulatory supervision. As well as publishing its annual balance sheet in a mass-circulation newspaper and posting the Sustainability Report on its website, Termomecanica has a system for rendering accounts, assessed by independent auditors, which includes various methods of disclosure, including email marketing addressed to customers and suppliers, and notices on the Mural Newsletter intended for members of the staff. There is full-time dialogue and engagement with key stakeholders. In the case of customers and suppliers, the process depends mainly on visits and official communications, apart from the Ombudsman, Customer Call Center (SAC) and opinion surveys. Our relationship with our staff is reinforced by the various formal communication channels existing in the company, as well as by meetings and special programs. Mutual respect is the basis of all Termomecanica’s relationships and is also a feature of our Code of Ethics and Conduct, which was updated and widely disseminated in 2014. As well as reinforcing the company’s principles, the Code lists practices that are expressly prohibited, including corruption and bribery involving outsiders such as the community, government, suppliers or partners. It makes it clear that all the company’s activities must be impartial, and that its legal and accounting advice must reflect these values.

Anticorruption practices and fair competition

Strict observance of the law has always been essential for Termomecanica. Thus the Code of Ethics and Conduct is uncompromising in its prohibition of active or passive corruption, with staff being urged to behave accordingly. There is an internal audit department with responsibility for ensuring that corruption does not occur. Internal practices include regular consulting of the SERASA and Ministry of Labor and Employment lists (“Blacklists”) to check that suppliers and customers are complying with the legislation. Termomecanica’s Competitor Relations Policy also gives guidance to staff on the importance of observing legal requirements. Among other things, this document prohibits staff from pointing out defects in competitors’ products or services as a way of promoting the company. Termomecanica is a company that insists on treating all its stakeholders ethically, and we have an Ethics Committee to look into reports of wrongdoing, including corruption, and to impose punishment when necessary.

Integrated Management System (SIG)

With the aim of ensuring good business performance and to reinforce our focus on sustainability, Termomecanica has introduced an Integrated Management System and assesses its performance according to a set of indictors. Each of the company’s processes is assessed according to targets set by the areas themselves and approved by senior management, with results being evaluated monthly and action plans introduced as necessary. The SIG focuses on the following key factors: Quality, Environment, HR, Finance, Legal, Industrial, Supplies, Sales, Engineering etc. The internal audit area takes preventive action, systematically and continually, in respect of financial and accounting transactions, validating internal controls and supporting the corporate governance system. External audit firms are engaged to act in parallel, as required by law, to examine the financial and accounting statements. Finally, Termomecanica also undertakes six-monthly audits of the Integrated Management System, to ensure that procedures are efficient.

INTEGRATED MANAGEMENT SYSTEM POLICY

Termomecanica operates in the domestic and international market for transforming copper and other non-ferrous metals into products, services and solutions. Our commitments are:

► To identify, manage and avert risk, on the basis of social responsibility;

► To meet the needs and the requests of our customers and stakeholders;

► To constantly improve the performance of our products and processes;

►To promote the health and safety of those involved, preventing injuries and diseases, improving ergonomic conditions and controlling the risk of accidents;

► To preserve the environment and prevent pollution, controlling the waste produced by the process and atmospheric emissions;

► To obey the law and the requirements applicable to the business.

HIGHLIGHTS OF 2014

► Start of the performance assessment program for management, by defining and monitoring individual targets, so as to identify the relationship between staff skills and performance;

► Intensification of programs such as the Leader Factory, focusing on management tools, and the Culture School, teaching organizational values and principles, as well as the Code of Ethics and Conduct;

► Start of specific programs for talent management, with a view to reinforcing the company’s succession plan and its long-term strategy and, as a consequence,its sustainability;

► Meetings with the entire staff to explain the content of the Code of Ethics and Conduct and its application in their daily work. Each participant received a copy and signed an acknowledgment of responsibility and commitment to the principles outlined in the document;

► Publication of the Code of Ethics and Conduct on the company’s website, with a marketing email being sent to suppliers and customers, containing a link to the document, to enable them to become familiar with Termomecanica’s principles and to share its values.

KEY TARGETS FOR 2015

► To reinforce the idea of values and ethical principles in communications;

► To query the National Register of Ineligible and Suspended Companies (CEIS) before engaging a supplier, as a means of combating corruption.

Social and environmental development

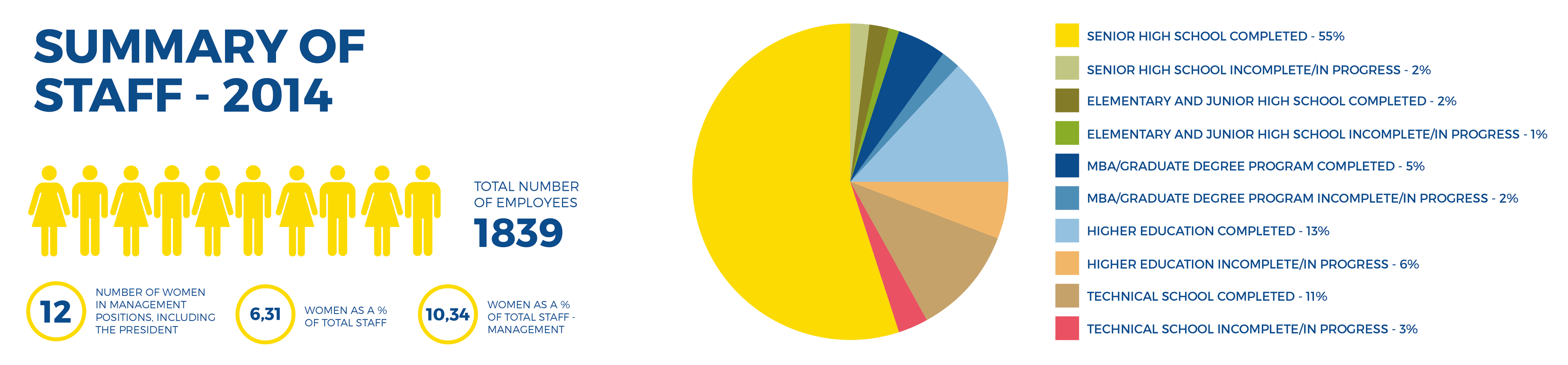

PEOPLE: Respect for human rights and diversity

We believe in the wealth of diversity and respect for people, and we make no distinction when hiring staff or filling positions; opportunities for development are available to everyone that meets our requirements. In our relationships outside the company the situation is the same. The company always seeks to adopt a posture combining concern for human rights and its business strategy, without focusing only on managing risks to its image. Since the start, Termomecanica has believed in professional development and in providing work opportunities without discrimination or favor of any kind. Our policy of encouraging diversity is reflected in our workforce. We stimulate teamwork, and our desire is that both success and failure be shared, while ideas are listened to with generosity and genuine interest.

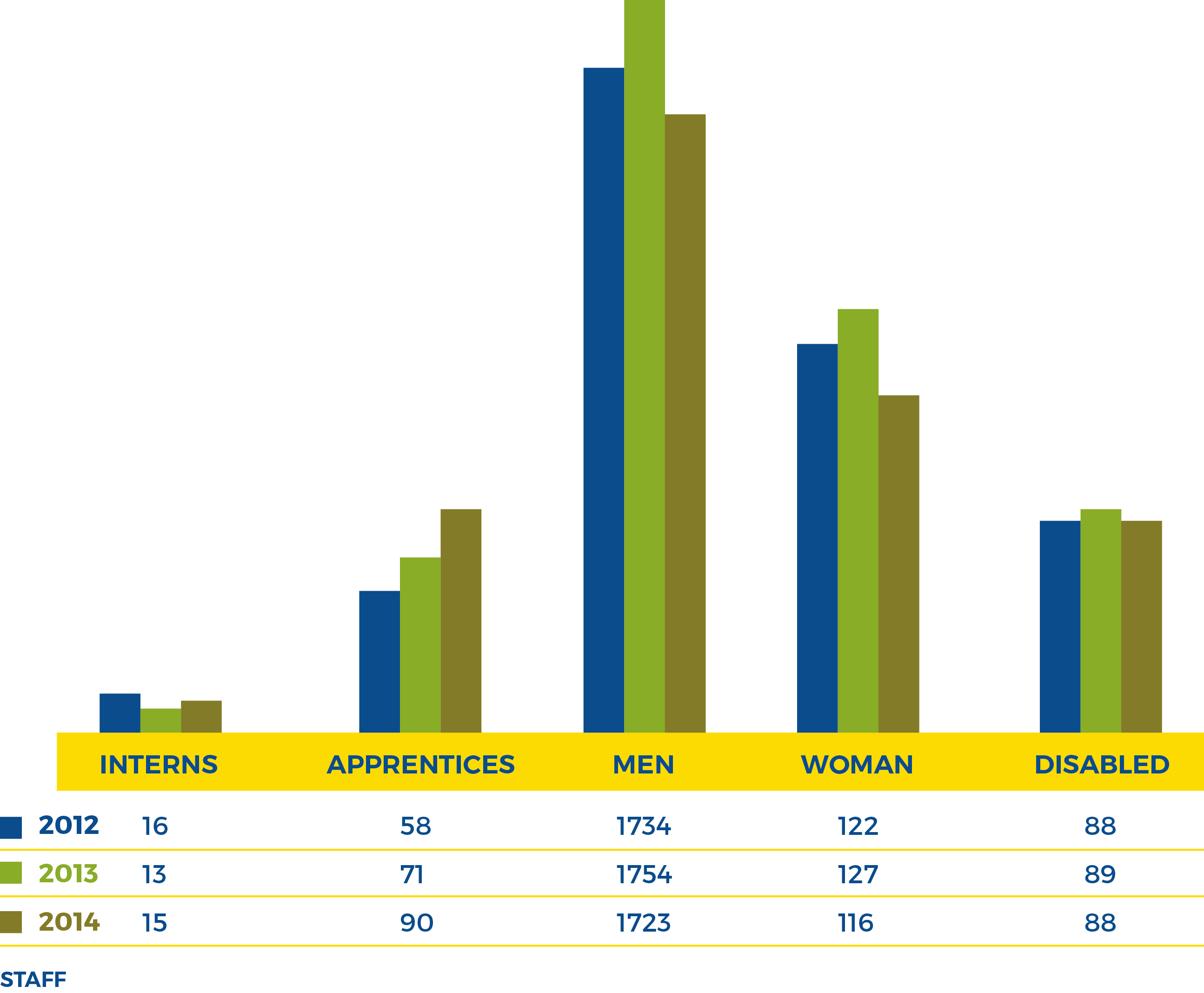

Inclusion and appreciation of young people

The same work philosophy applies in managing interns, and the company complies with all the provisions of Law No. 11788/2008. Our objective in hiring and supervising students is to provide them with professional training, involving social, professional and behavioral learning, as the context of the job requires. Interns are allocated to different areas, and are given preference when a vacancy occurs. Seven of the 14 young people who completed their internship with TM in 2014 were hired, giving a 50% success rate.

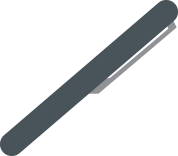

Othe Apprentice Program, in partnership with NURAP and CIEE (for hiring young people in administrative areas) and with SENAI (for maintenance areas), was enhanced in 2012, resulting in the Production Line Operator Apprentices Program. A partnership with the Salvador Arena Foundation, this initiative benefits young people between the ages of 18 and 22, from families with a per capita income not exceeding one and a half minimum salaries. The scheme enables them to enter the labor market and prepares workers for future positions with Termomecanica. In 2014, the company had 90 apprentices, and 9% of them were subsequently given full-time employment.

Another constant preoccupation of Termomecanica is to allow handicapped people to develop their professional abilities and to give them the opportunity to enter the jobs market. They are always placed in sectors indicated by a risk mapping report. We focus on individual talent, not their limitations

Today the company meets the law’s quota requirements in full, mainly with people who have hearing problems, although we have staff with physical and visual difficulties as well. We therefore have a full-time LIBRAS (Brazilian Sign Language) interpreter in the plants. Groups of managers and staff are also trained in sign language, to facilitate social interaction and integration even more.

Development and careers

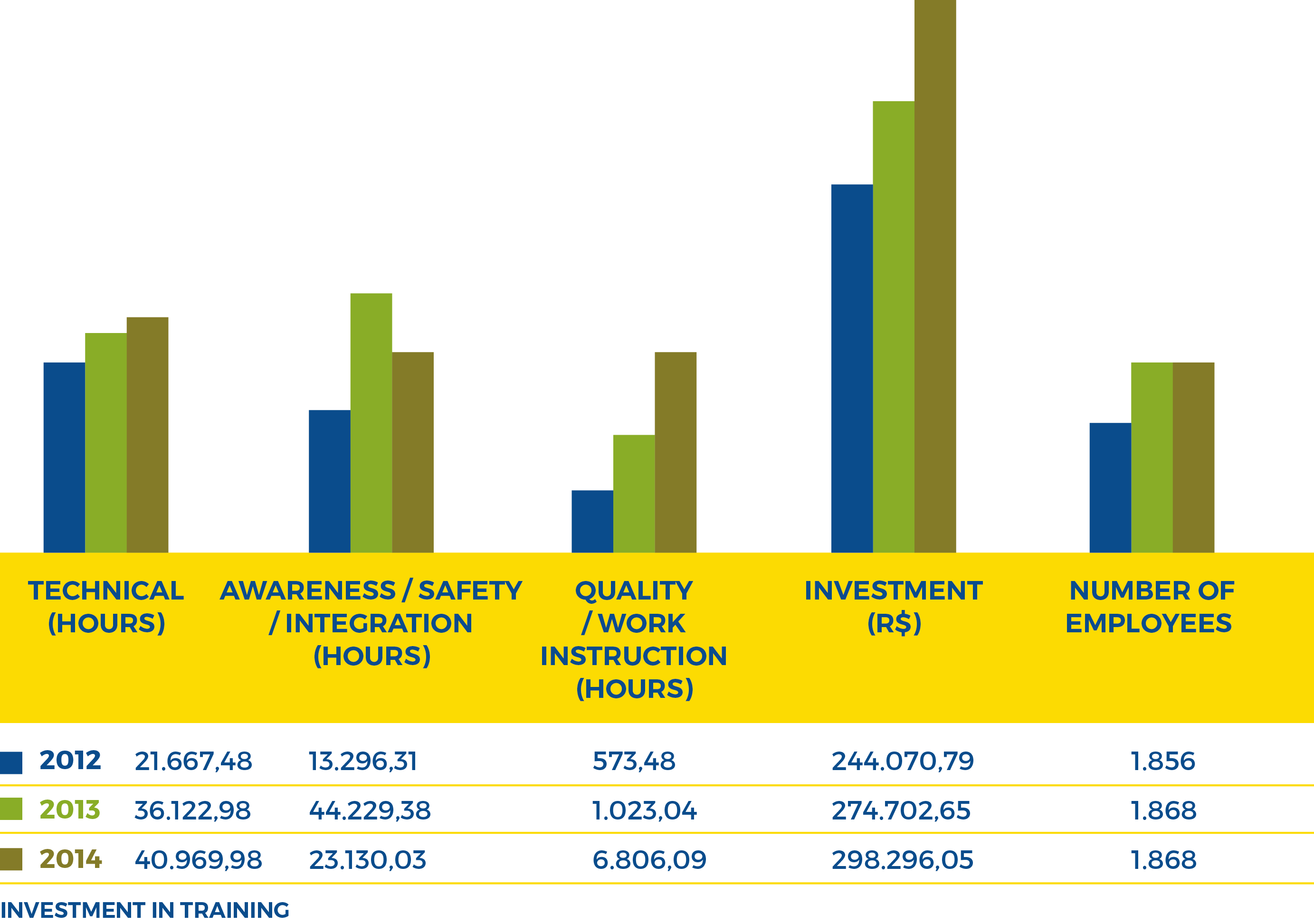

One of the challenges continually faced by TM is to make the most of all our internal potential and to offer the chance for career progress, thus keeping the team motivated. To this end, the company gives precedence to its own employees, or to people they recommend, when filling vacancies, which are publicized first on the Bulletin Board Journal and the corporate website, on the intranet. The Internal Recruitment Program is comprehensive and involves an assessment of a CV, written and practical tests, an interview and a medical exam. In 2014, of 251 vacancies, 137 were filled internally, thanks to this policy. To measure salary bands for different positions, Termomecanica compares them with the market average, so as to keep compensation in balance both within the company and externally. Salary surveys are undertaken frequently, to maintain an attractive level of compensation which is compatible with career prospects, and to provide an interesting environment for the professional development of our staff. Termomecanica is also a leader in professional development. Since 2006, we have had a systematic training program for all employees, to provide technical and operational training and furnish them with tools of quality, productivity, safety and management. Each member of the staff had an average of 38 hours of training in 2014, in both in-house and external courses. Training effectiveness reached a ratio of 90%.

Types of training

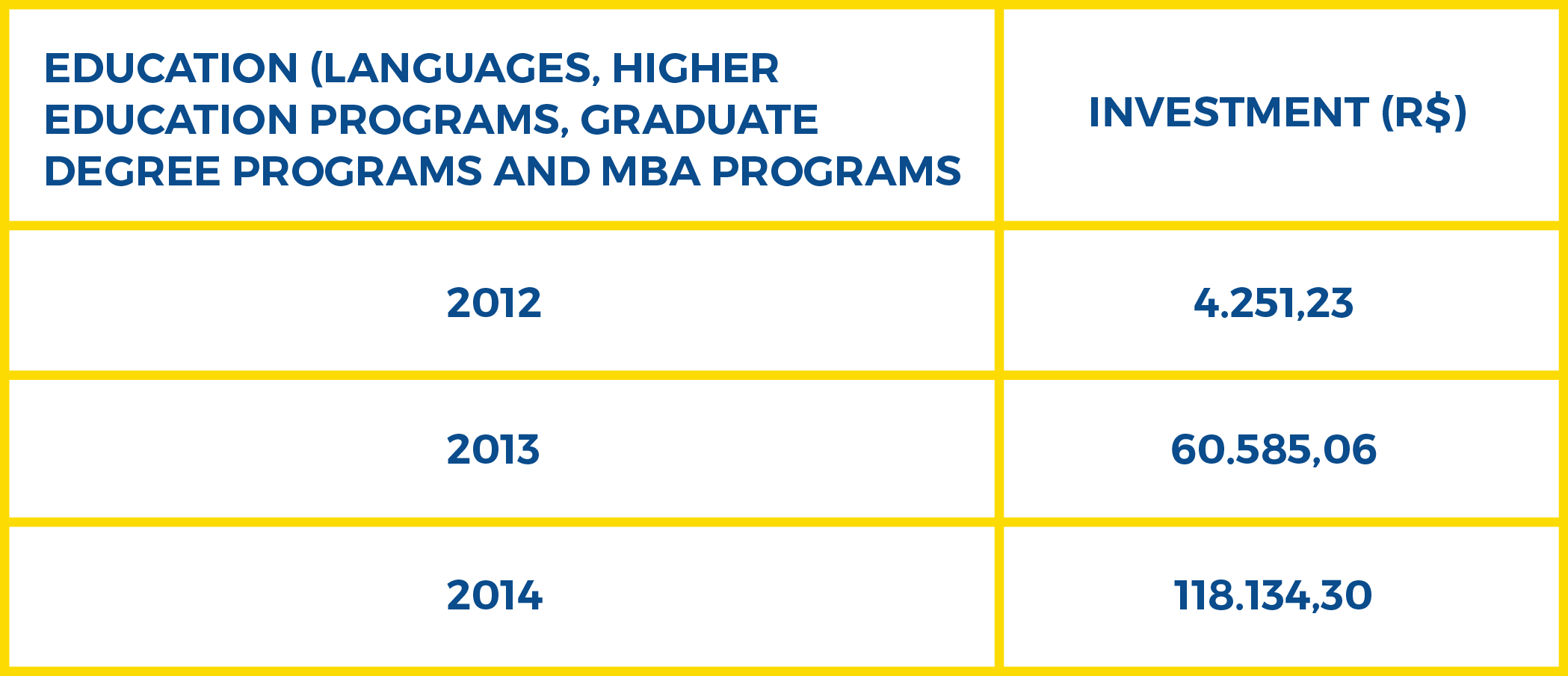

Termomecanica’s annual training program is based on learning and qualification requirements for positions, skills assessment and individual staff development plans. This system determines the methods for planning, control and verification of the effectiveness of training provided, which can be of several different types: Internal – Training in the workplace for new staff, as an integration process or to teach daily routines. This training is provided by in-house multipliers, with the help of a checklist for content and recording. “Knowledge Trail” – Introduced in 2014, initially in Plant II, it involves distance learning for factory staff. Procedures, working instructions and operating and safety documents have been adapted for e-learning, making them easier to read and allowing for comprehension of the content to be assessed. The initiative permits recording of practical training and approval by the manager, with certificates being issued and the multifunctionality matrix updated automatically. Languages – For staff who use a foreign language at work or for their development within the organization, Termomecanica bears 85% to 100% of the cost of a course for up to two years, limited to R$500 per month. Seventeen employees attended English or Spanish courses in 2014, for a total investment of R$17,667.50. Supplementary Courses – These courses supplement training and professional development, and are 100% subsidized by the company, provided that they are in line with employees’ Individual Development Plans (PDIs) and the Annual Training Program. Higher Education Programs, Graduate Degree Programs, MBA programs, Extension Programs Abroad and Master’s Degree Programs – The company can reimburse up to 50% of university costs and up to 100% of graduate degree programs, MBAs, Extension Programs Abroad and Master’s Degree Programs, subject to the following requirements: the course must be aligned with company strategy and professional development for the current position or the future career of the employee; the employee must have been with the company for at least one year (including time spent as an apprentice or intern, if any); and it must be authorized by the Executive Board/CEO.

Termomecanica Corporate University

With its links to the Salvador Arena Foundation, the Termomecanica Corporate University (UCTM) is intended to help the professional development of staff, partners, customers and suppliers, focusing on the skills the company has selected as being essential for its future, and thereby bridging the gap between human and organizational attributes. The program is open to all staff, but selection depends on the recommendation of managers and HR, based on overall Skills Assessment marks, on Individual Development Plans (PDIs) and on the needs of career planning and business strategy. Divided into General (for all staff), Management (leaders) and Functional (operations and administrative positions), the skills taught represent an investment in employees according to their career progress and the complexity of their positions. The UCTM development grids are subdivided according to organizational guidelines into: TM Academy, Culture School, Management School and Operations School. Training offered includes technical and behavioral courses, lectures and other learning tools. In 2014, a total of 221 development courses were held for key stakeholders, with 4141 students taking part and more than 1200 hours of training being given – some 8 months full-time activity. TM Academy - Teaches skills to partners, suppliers and customers, with the aim of securing the future of the Salvador Arena Foundation and its subsidiaries. Topics covered include: Non-Ferrous Metals, TM 23 Bronze and TM 620 Bronze Courses; Installation of Termomecanica Copper Tubes and Connections; Applied Metallurgy in Copper and its Alloys; and Customer Service. These courses are given in partnership with Senai, and qualify students in various areas for the proper use of the company’s products. The Academia TM also provides the “Get to Know TM” program, which offers students an insight into the market where TM's products are sold, and includes a visit to the industrial park in São Bernardo. In 2014, the TM Academia took 918 students, with courses for partners totaling 144 hours.

Culture School - Intended to instill an appreciation of the organizational culture and its influence on daily routine, and to reinforce the philosophy, principles and values of the Salvador Arena Foundation and its subsidiaries. In 2014, the Culture School offered its “Corporate Values Program”in order to disseminate FSA/TM values and the Code of Ethics, and to give staff a better understanding of them. 422 hours of training were held, divided into 98 groups with a total of 1734 participants. Management School - Provides the skills required by staff of the Salvador Arena Foundation and its subsidiaries, so as to consolidate the management model (processes, practices and tools) according to the core activities of each company. In 2014, the Leader Factory and Management by Process programs (introduced in 2013 and intended for management and administrative staff, respectively) were improved and extended. 78 courses were given, lasting 412 hours. Operations School – Intended to broaden Termomecanica employees’ knowledge, principally those involved in core activity operations, related to raw materials, the transformation of non-ferrous metals and the production processes. In 2014, the Operations School continued to offer its Basic Non-Ferrous Metals Course and introduced an Intermediate Course. Thirteen groups were given training, for a total of 268 hours. Distance Learning – The Termomecanica Corporate University offers more than 300 distance learning courses, in the form of video classes, organized into eight skills and some 40 sub-skills. In 2014, 888 certificates were issued for 980 courses completed by 340 TM employees.

A healthy climate for everyone

Termomecanica does not under any circumstances condone labor conditions analogous to slavery or the use of child labor, either in its own companies or by suppliers or business partners. Any violation of human rights can and must be reported, via email to ouvidoria@termomecanica.com.br. In agreements for the purchase of products or services, clauses are also included banning any type of discrimination or degrading working conditions. Suppliers that do not respect these terms are removed from Termomecanica’s approved list and reported to the Ministry of Labor. In general, working relationships are valued and operate ethically and professionally. The company recognizes unions as the legal representatives of its staff, and seeks to solve labor or union conflicts through constant dialogue, to ensure good relations between the parties. This is also a constant challenge for Human Resources, which works systematically to apply the best market practices to the company’s business.

Benefits above and beyond

The culture and values of Termomecanica include offering its staff special benefits, most of them provided voluntarily and without financial return.

Health, our top priority

Medical assistance is one of the highlights of our benefits package. With more than 5000 cases in 2014, the healthcare plan available to all staff and their legal dependents provides coverage according to the Private Healthcare Agency (ANS) list, with monthly dues paid in full by the company, a countrywide accredited network and a reimbursement system for expenditure outside the network. A number of programs were improved in 2014, in partnership with the insurer, to improve the quality of life of the users. Another important benefit is the dental plan. Provided free of charge to all staff and their legal dependents, the plan covers the whole country, with 93 additional procedures and types of coverage, such as partial and full prostheses, resin crowns and fillings, etc. To help employees use the medical and dental care schemes, Termomecanica and the insurance broker jointly provide a service for scheduling appointments and medical tests, handling reimbursement applications and authorizing tests and surgical operations. As well as that, in the area of healthcare, the Drugs Benefit Program (PBM) was also a highlight of 2014. It offers staff and their dependents two lists to choose from – one of them with drugs 100% subsidized by Termomecanica and the other with discounts of up to 60%.

PROGRAMS IMPROVED IN 2014

PAQV (Amil Quality of Life Program): An initiative to encourage the prevention of disease and promote health and wellbeing. In-company interviews were made to help identify health-related risks early. UCP (Posture Correction Unit): Program for treating and preventing postural disorders. The third group, consisting of 41 employees, entered the program in 2014. MOTHER & BABY: Relationship and guidance program for pregnant women, with post-natal monitoring of the baby up to one year of age. The Benefits area also prepared a pamphlet showing all the rights and duties of pregnant employees. RADAR: A program to identify the most frequent users of so-called low-complexity events (doctor’s appointments, tests and procedures) to provide guidance and direction in the correct use of resources. GPAR (High-Risk Patients Management): A program to identify beneficiaries with a high risk of developing chronic illnesses. It classifies, allocates and monitors them in all medical aspects of their lives, and intervenes positively to improve their health and quality of life.

Quality of life always to the fore

A number of other benefits related to quality of life are traditionally offered to the company’s employees. Termomecanica maintained its package of options in 2014, helping to ensure peace of mind for its employees and their dependents: DAYCARE ALLOWANCE/REIMBURSEMENT - As agreed in the category employment terms, Termomecanica provides a daycare allowance or reimbursement for its staff, until their children reach 2 years of age. PRIVATE PENSION SCHEME - Termomecanica offers all staff a private pension scheme, contributing 80% of the cost of the retirement benefit and 100% of the cost of the risk benefit (insurance). The plan also offers technical and financial terms that are better than the market average. TRANSPORT - The company provides a number of chartered buses free of charge for the staff. For those that live more than 1.5 km from the bus routes, transport vouchers are provided. The company also provides free parking near the plants. FOOD - Termomecanica has 24-hour self-service restaurants in the plants. They provide various meals during the day, with quality control and special menus for those with dietary needs (diabetes, high blood pressure or obesity) monitored by nutritionists. The restaurants are managed in-house, and so the company is able to better control costs and the commitment of the team, and to avoid waste, with leftovers and waste being controlled monthly. Regular tests are carried out at an independent laboratory for the microbiological control of the food served. FOOD VOUCHERS - Termomecanica gives all its staff food vouchers for values higher than the market average, fully subsidized by the company. In December, as a special gesture, the company gives double the value of vouchers to help during the holiday season. ARRANGEMENT WITH SOCIAL SECURITY - Termomecanica has an arrangement with the INSS agency in São Bernardo do Campo to speed up procedures for sickness benefits, work accidents and retirement benefits for its staff.

Partnership with the Salvador Arena Foundation

Termomecanica and the Salvador Arena Foundation have introduced a number of other projects to benefit the employees: Solidarity and Mourning Program - Provides caring professional attention to employees and their families who have lost a loved one, to show respect, solidarity and consideration on the part of the company. There were ten cases in 2014: two employees died and eight family members of our staff. High-cost Drugs and Medical Tests - Enables employees and dependents to have access to expensive drugs and medical tests not covered by government programs or by the company medical or dental schemes. Fourteen employees were helped in this way in 2014: two by cash donations and 12 by guidance on obtaining government help or coverage under the medical plan. Assistance to Employees with Disabilities - Financial and technical help is given to buy expensive prosthetics, orthotics or special devices to improve the quality of their lives, socially and professionally. In 2014, one employee of Termomecanica and two of the Salvador Arena Foundation were given this kind of assistance. Family Emergency Help Program (PAEF) - Intended to support and encourage employees undertaking supportive, charitable or humanitarian actions, by providing technical and social advice and a cash supplement for supplying basic necessities to low-income families, or those with no income, which are socially vulnerable or at risk. In 2014, 365 employees took part in the program, providing direct assistance to the same number of families (a total of about 1205 people).

“Top Marks Volunteers” Campaign – Advises staff on how to make use of São Paulo Tax Receipts to the benefit of social entities, recommending donation to Non-governmental Organizations (NGOs) monitored by the FSA, which makes technical visits and periodic accounting checks to ensure that the funds are properly used. Nearly nine thousand tax receipts and coupons were collected in 2014, and they were donated to four social organizations. TM Cultural Center (ECTM) – Provides access to knowledge, connecting employees to the main information media and modern methods of learning. With an area of around 1400 m², the TM Cultural Center has internet, a library, CDs and films for borrowing, study rooms and projection rooms, and social areas. The library has about 4500 books and there are some 500 CDs. The latest magazines and periodicals are available. There are 38 computers for internet access. The games and TVs contribute to staff entertainment and leisure during rest periods. Through a strategic partnership to promote TM’s educational aims, staff also have access to a virtual university library, and can enjoy hundreds of books from top publishers in different areas of study. The online system is available full-time, without charge, and offers advanced tools for research and accessibility resources for the visually impaired. Extension of medical and dental schemes for former employees – Ex-employees with more than 10 years of work in the company and their legal dependents are covered by medical and dental schemes for 6 months after they leave. Former employees are entitled to medical and dental schemes for an indefinite period if the sum of their age and the time worked in the company is at least 85 years.

HIGHLIGHTS OF 2014

► 5001 lives covered by medical and dental schemes ► 112 daycare allowances/reimbursements provided; ► 1839 active private pension plans; ► 1285763 meals served in the company’s two restaurants; ► 22011 food vouchers given out; ► 1215 drugs donated. KEY TARGETS FOR 2015 ► Partnership with a club to encourage physical and leisure activities, to encourage integration and improve quality of life; ► Improving the perception of employees and increasing the benefits package without affecting the budget.

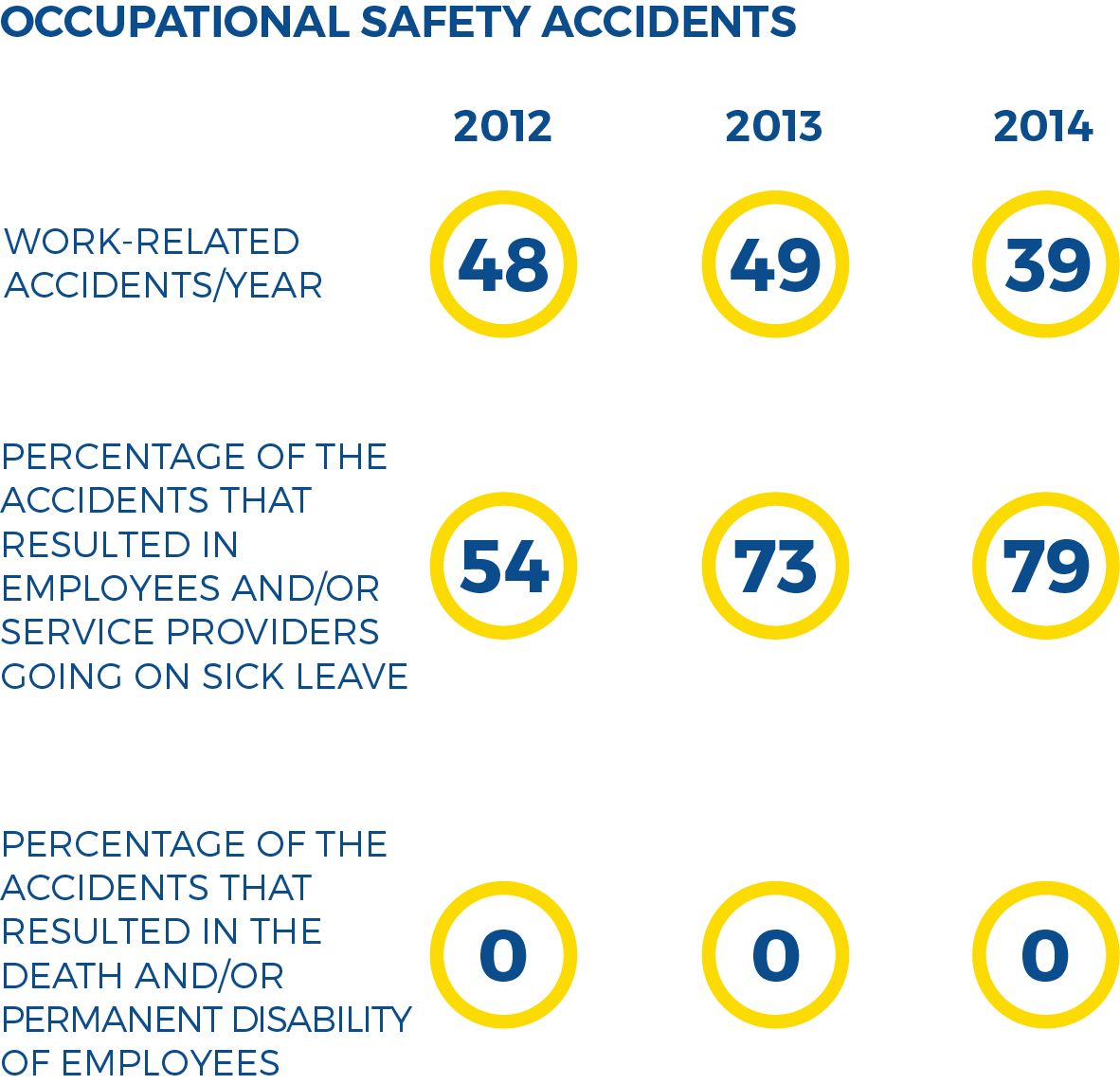

OCCUPATIONAL SAFETY: A safe environment at all times

Working for Termomecanica means experiencing an environment where people are serious about the standards, legislations and procedures involving safety. The company has traditionally sought continuous improvement in its employees’ working conditions, thanks to a series of practices that are already part and parcel of their day-to-day activities, including: ► Adoption of the “Safety First” tool, for the purpose of behavioral assessment of occupational safety, whereby the employees are encouraged to actively participate in identifying risks and types of behavior, as well as suggestions for corrections to work stations; ► Control of legislation applicable to the company’s business activities; ► Risk analysis process for change management; ► Continuous detection of hazards, as well as control of risks; ► Analysis of sporadic activities and those carried out by contractors, using a specific form; ► Emergency system maintenance, including periodic testing of the scenarios already mapped out, training for employees comprising the safety teams, escape routes, emergency kits strategically located throughout the plants, in addition to periodic simulations of emergencies and evacuation of the areas; ► Periodic training sessions, both to comply with the law and to continuously improve the system; ► Periodic checks that the requirements established are being complied with, through internal and external audits; ► Training for new hires and service providers; ► Ergonomic committee in charge of implementing the improvements identified in the ergonomic studies of the activities;; ► Employees are constantly notified through articles published in the in-house communication vehicles and in the Safety Dialogs.. Besides encouraging safe behavior, in 2014 Termomecanica also invested heavily in protection regarding machines, as well as training and awareness, and, as a result, the company reduced the frequency rate of occupational accidents by 20.4%. The investments amounted to R$2,948,775.00 in projects such as: ► Modernization of the Plant II fire alarm system; ► Implementation of Work Instructions for Safety Inspection and Work Instructions for Working at Heights; ► On-going implementation of protection regarding machines in order to fully comply with Ministry of Labor ruling NR-12; ► Enhancement of the emergency control system, with the acquisition of incident response equipment; ► Carrying out of safety campaigns, such as the Internal Accident Prevention Week (SIPAT), Safety in Your Hands and safety training upon returning from the year-end vacations period.

Protection equipment

Those working at Termomecanica are entitled to all kinds of guidance regarding the proper use of personal protection equipment (PPE), which abides by the technical specifications of the safety area. PPE is distributed to all employees, and they must wear it as they are subject to inspection by occupational safety Technicians. For the company, preventing occupational accidents involves not only modernizing the manufacturing processes and improving infrastructure; it also involves, above all, the team’s awareness of safety issues. To that end, training is constantly provided, in addition to holding events like the Internal Occupational Accident Prevention Week (SIPAT), as well as maintaining an Emergency Response Team consisting of employees from the different areas of operations and who are properly prepared to ensure best procedures in the event of an emergency.

Contractors and visitors

Just as important as the safety of its own team, is that of its contractors. In their case, the company has developed a specific prevention system equally efficient. Using the corporate portal, managers register in detail the activities that contractors are to carry out. Then, the Occupational Safety and Medicine teams analyze the risks, while the HR department analyzes the contract of employment documentation. Once approved, safety, risk analysis and the Work Permission License (APT) are integrated so that the services can go ahead. Every day, the risk analyses are reassessed by management, while the employees are immediately reinstructed when any deviations are detected. Contractors have access to the information through the contract manager responsible for keeping the documentation and for monitoring that the activities are carried out as planned and approved. Every year, all contractors have to undergo safety integration recycling. Visitors also come in for special attention: when they enter the company they receive the Visitors’ Manual containing instructions about safety procedures and environmental care.

HIGHLIGHTS IN 2014

► 20.4% reduction in the number of accidents in relation to 2013; ► 27.41 hours of training accumulated; ► 82% fulfilment rate for ergonomic actions.

KEY TARGETS FOR 2015

► Promote improvements in 75% of the hazards identified and classified with an NPR (Risk Priority Level) exceeding 243;

► Deploy at least 75% of the actions identified in the Safety First tool;

► Awareness about safe behavior, with a target of 95%;

► Provide employees with at least two hours’ training per month on issues involving Occupational Health and Safety;

► Reduce by 15% the number of incidents, the severity rate and frequency of accidents.

HEALTH: Quality of life for our greatest asset

The health of its employees is one of the most important issues for Termomecanica, and as such it receives special attention.

With the focus on education and prevention, more than 30 communiques were published dealing with health, in the company’s various in-house communication vehicles. Proper hygiene, the prevention of seasonal illnesses and epidemics, memory and sleep are just some of the texts that were published in manner that is objective, succinct and easy to understand.

In 2014, prescriptions for broad spectrum worm treatment medications continued to be issued to all employees, free of charge, thanks to the company’s free medication benefit program.

The Medical Control and Occupational Healthcare Program at Termomecanica, which is both educational and preventive in nature, includes talks and in-house events whose aim is to promote the well-being and quality of life of its employees.

► Prevention of AIDS and other sexually transmitted diseases, through the distribution of male and female contraceptives to employees and service providers;

► Guidance on smoking, health diets, diabetes, high blood pressure, obesity, dyslipidemia, memory and physical activity, etc.;

► Guidance on preventing prostate cancer, focusing not only on age, but also on family history and the demystification of recurring doubts not raised;

► Guidance on the prevention of cancers most frequent in women, precautions, fears and doubts open to knowledge;

► On the special dates allocated to this issue of preventing prostate and breast cancer, the highlight are the clothes worn by the administrative employees of Termomecanica in colors that allude to the event;

► Fostering proper hygiene of the hands on posters put up at the company’s key access points;

► Guidance on preventing illnesses like dengue fever, tuberculosis, Ebola, kidney stones, Chikungunya fever, Conjunctivitis, etc.;

In 2014, Termomecanica pushed ahead with the program for monitoring employees with drug addiction, consisting of outpatient treatment, psychotherapy and hospitalization. The results of the assessments were positive, with no relapses in outpatient cases. Under the medical plan, the company has an agreement with a specialized healthcare institution that affords much wider and specific treatment, in addition to long-term monitoring.

Health profile assessment

TM’s concern with the health of its employees commences as soon as they are admitted to the company. During the first month after admission, Termomecanica asks them to undergo examinations of a preventive nature in order to define the employee’s health profile. After analysis by a physician, and with their consent the employee may be directed to the Differentiated Dietary Program (PAD), the Anti-Smoking Program, recycling regarding the vaccination scheme, medical specialists and others. In 2014, 254 employees underwent this process. And that’s not all. Employees suffering from chronic illnesses like diabetes, hypertension, obesity, dyslipidemia, as well as smokers, are instructed and/or directed to look after their health, and their adherence is monitored as soon as the illness is diagnosed during the periodic check-up or during a medical appointment. Follow-ups of complex cases are monitored bringing forward appointments, examinations and contacts with assistant physicians in order to provide a better, faster and more effective response.

SPECIAL PROGRAMS

Differentiated Dietary Program (PAD) - Its purpose is to improve the quality of life of employees with high blood pressure, diabetes mellitus and obesity by providing guidance and a specific and balanced diet. They are evaluated by the occupational physician, in a clinic and/or via laboratory tests, in addition to regular outpatient appointments for specific control. They are also directed to the dietary service of the restaurant, which can provide the diet indicated in the program. As a result of this, 3,812 dietary meals were served ever month at Plant I and 830 at Plant II during 2014, serving 283 people. Anti-smoking Program - Promotes individual guidance on cigarette addiction, the harm it does, dependence mechanisms, options for treatment and the side effects of medication and abstinence. Participation is spontaneous, and the treatment employs nicotine patches provided free of charge to all participants with weekly control. In 2014, 10 employees signed up for the Program, of whom 5 have quitted smoking. A total of 24 boxes of the medication were distributed. Vaccination Control - This is the responsibility of the Occupational Medicine Department during the periodic check-up, with systematic control of the employees’ vaccination booklets from the time they are hired, recommending that these be kept up to date in accordance with the National Immunization Program – PNI. Anti-tetanus vaccination is mandatory for all employees, in accordance with the PCMSO (Program for Medical Control in Occupational Health), while vaccination against hepatitis B is mandatory for all members of the emergency response team and healthcare staff. Ergonomics Program - This aims to promote adjustment of work stations to the worker by means of modifications to layouts and processes in which the workers effectively participate alongside the technical team and senior management. 2014 saw the conclusion of the fourth and final phase of the Program, under the supervision of specialist consultant Prof. Dr. Hudson de Araújo Couto, an ergonomist globally recognized for his studies and results. As from 2015 onwards, the program will be managed by the committees and officers of Termomecanica, putting in place the recommendations and technical standards.

HIGHLIGHTS OF 2014

► 100% of the diabetics monitored; ► 100% of the periodic check-ups carried out within their respective validity periods; ► 100% fulfilment of the target for preparing/disclosing healthcare notifications.

KEY TARGETS FOR 2015

► Continue to monitor at least 90% of the diabetics; ► Monitor at least 90% of those suffering from dyslipidemia; ► Prepare and circulate at least one healthcare notice every two months; ► Carry out periodic visits to work stations (physicians/nurses); ► EForward employees for cholesterol, triglycerides and blood sugar tests.

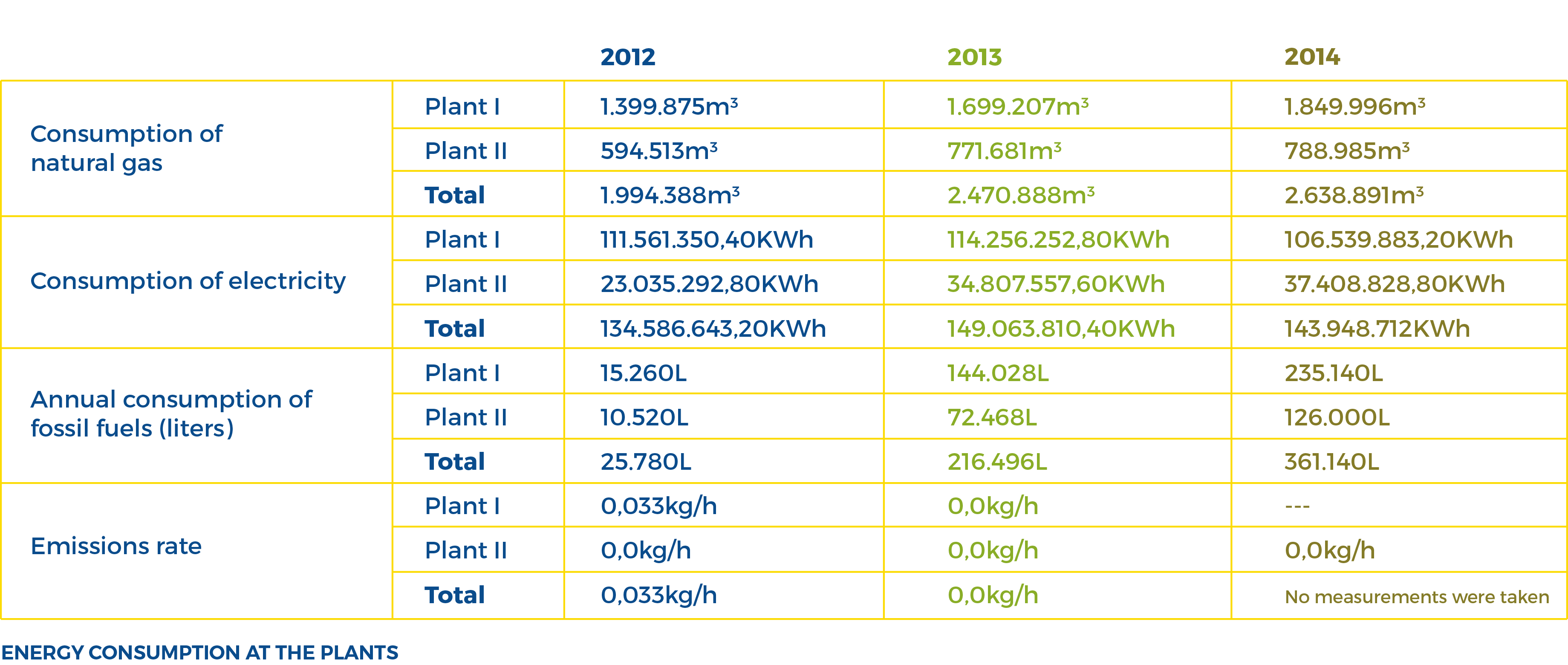

THE ENVIRONMENT: Ensuring the future of new generations

Respect for the environment is an attitude that is encouraged and valued by Termomecanica. The gradual awareness of all employees about the environmental issues in their work and family life was one of the major advances in 2014, and explains why the company has been so successful in the initiatives taken. The rates of atmospheric emissions from the manufacturing processes, for example, are below the limits imposed by the environmental bodies, while all emissions are mapped when so required. To maintain this positive scenario, Termomecanica participates in study groups engaged in the disposal of waste and control of atmospheric emissions, both at local and state and federal levels. The proper disposal of the waste produced from its operations is another important aspect in this context. The companies responsible for treating the volume of waste produced are audited in advance and trained in line with internal procedures. At the same time, the company permanently monitors internal waste generation so as to reduce it. One of the methods used is Selective Garbage Collection in all department of the company, where the aim is to correctly separate and dispose of the waste.

A permanent compact

The Termomecanica environmental compact is described in the Policy for the Integrated Management System, and its success is reflected in the maintenance of ISO14001. The efficiency of the SGA (Environmental Management System) is subject to periodic assurance by internal and external audits. The environmental management plan contains the procedures for complying with all the legal requirements applicable to the organization, management of all waste generated, control of all aspects thereof and the environmental impacts, in addition to dialog with stakeholders. The initiatives taken at Termomecanica are part of the joint programs defined by the sector responsible for the environment with each area of the company. All plans in progress are monitored as to their progress and compliance with the targets and objectives presented. In addition, periodic meetings are held for a critical analysis of the system, where the company’s environmental issues are discussed and the proposed projects aligned. Proper analysis of the data enables decisions to be taken, in addition to providing guidance on new investments and means of control. It is important to recall that TM continually monitors the legal requirements applicable to its processes using an on-line system, which makes it easy to consult documents during audits and technical visits. Termomecanica also employs procedures for controlling the pollution caused by its own and third-party diesel-powered vehicles. A daily sample is taken of the quality measurements of the smoke emitted through the exhaust systems of the vehicles that enter the premises, and deviations are notified to the person in charge. The in-house fleet is subject to rigorous control, with the vehicles undergoing periodic maintenance to ensure they are working properly. The concern with environmental issues also applies to the company’s suppliers, who are evaluated for their activities and are required to present environmental documentary proof that their processes are being monitored. Suppliers will not be given clearance in the absence of these documents.

Emergency plan and environmental education

At Termomecanica, the members of the emergency brigade are trained in periodic simulations of environmental emergencies so as to evaluate the attitudes adopted at the plants. The emergency situations identified in these processes are covered by pre-defined internal procedures to ensure the efficiency of the system. Besides the Emergency Plan, the company also invests in initiatives dedicated to environmental education, primarily to raise awareness among the internal stakeholders. Besides the frequent coverage allocated to the issue in the in-house communication vehicles, Termomecanica provides training given by supervisors who focus on the role of each employee and how they contribute based on their day-to-day activities. This type of action involves recurrent themes such as waste disposal, conscientious consumption of natural resources and atmospheric pollution. Information that is more relevant and directly applicable to certain areas is provided through the Internal Accident Prevention Week (SIPAT) and training courses that are directly aligned with the HR area, taking into account the activity-linked competency of each employee to be trained. The next step is to create other initiatives intended for the employees’ family members.

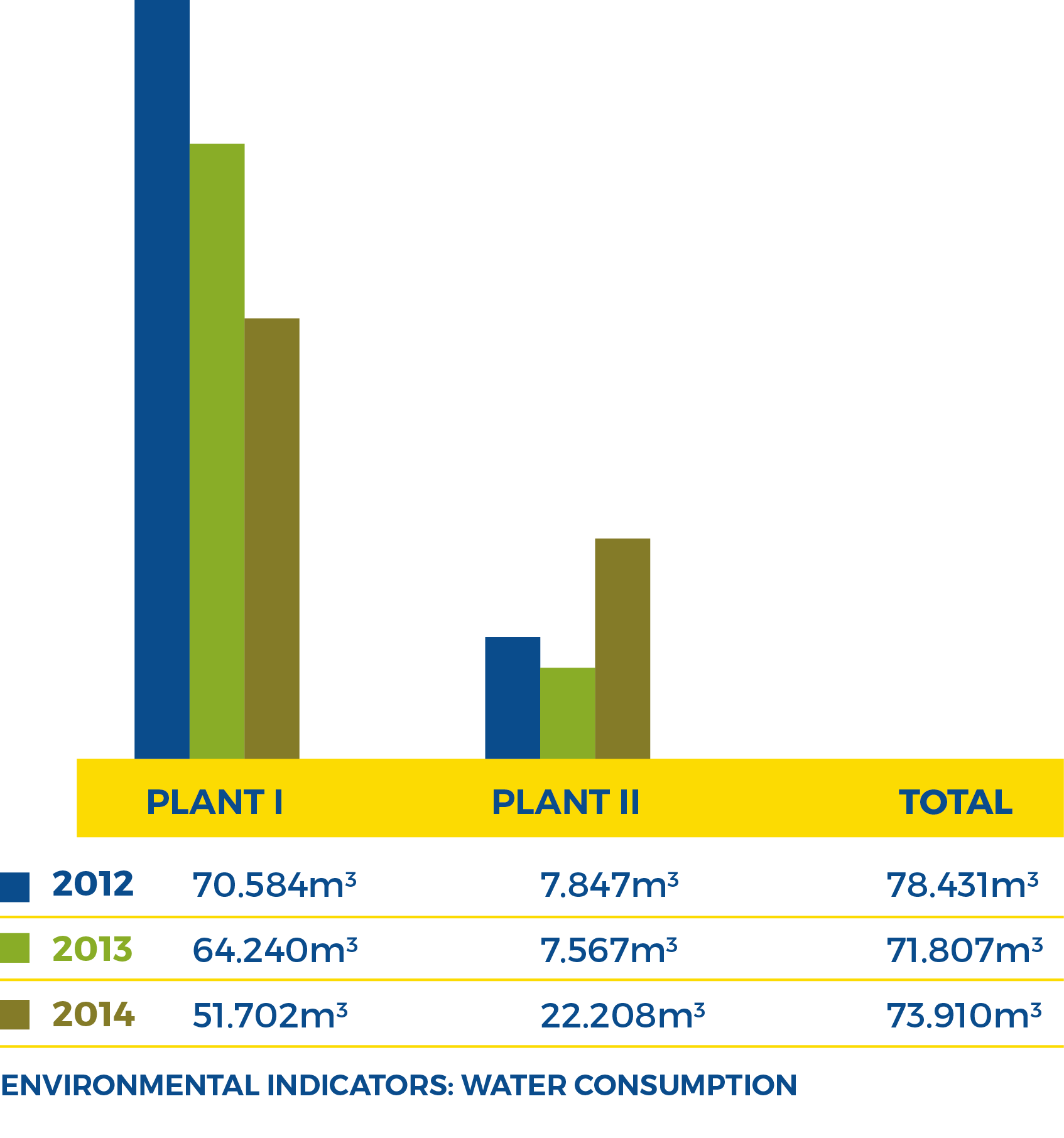

Water and electricity, two major challenges

Internally, the company provides periodic training involving several issues related with the environment, in addition to engaging in specific awareness campaigns on matters of general interest, such as the ration use of water and energy resources. Also, it continually maps all types of use involving natural resources. In the case of water consumption, for example, the company has invested in new equipment that enables optimal consumption in its daily operations. In 2014, the results were excellent, even though Plant II saw higher water consumption. This was due exclusively to the processes deployed during the installation of new laminators and milling cutter and the Tubes Unit, which has established new indicators to be pursued as of this year.

The same applies to electricity consumption. The company has been acquiring new, more energy efficient equipment, while decommissioning older equipment. It is also expanding its energy matrix by using natural gas in the industrial ovens, a much more economical and ecological option. In 2014, the installation of the new laminators, milling cutter and the Tubes Unit also led to higher consumption of electricity and fossil fuel, which had been expected on account of the new processes initiated at the location. It is also important to recall that the emissions rate will only be taken in 2015, as it is measured every two years.

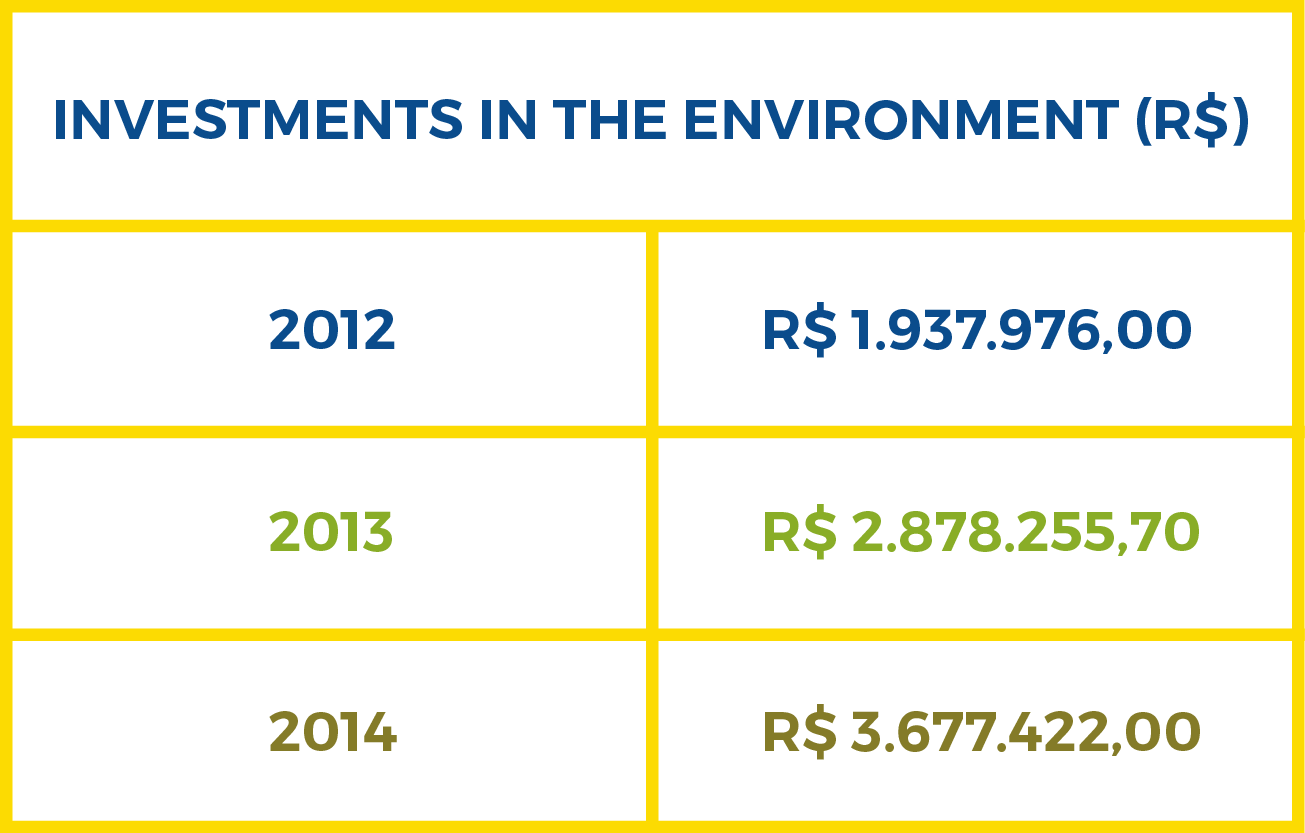

Investments in the environment

The importance that Termomecanica assigns to the environment can also be assessed in figures. In 2014, R$3,677,422.00 were invested in adapting equipment and processes. The priorities were the refurbishment of the building superstructures and the installation of control and monitoring equipment on some machines, which accounted for R$3,228,000.00. A further R$449,422.00 were used to investigate environmental liabilities and in miscellaneous analyses For 2015, new projects are under analysis and, even before final approval is given, one can identify the controls required, ensuring that they are appropriate prior to being cleared for execution.

HIGHLIGHTS OF 2014

► Reduction of 20% in water consumption at PI; ► Increase of 21.7% in investments in the environmental field; ► Preparation of the company for maintaining production levels, even with electricity rationing of up to 30%; ► Staging The Environment Week, with the theme: “What we have to do to save the planet”, for the purpose of involving and raising the awareness of employees and their families about their responsibility towards environmental conservation while showing the role of Termomecanica within the same theme.

KEY TARGETS FOR 2015

► Ensure production levels are maintained, bearing in mind the continuity of the crises involving climate change; ► Encourage even further reductions in waste generated and in water consumption.

Value Chain

SUPPLIERS: Efficient business partners

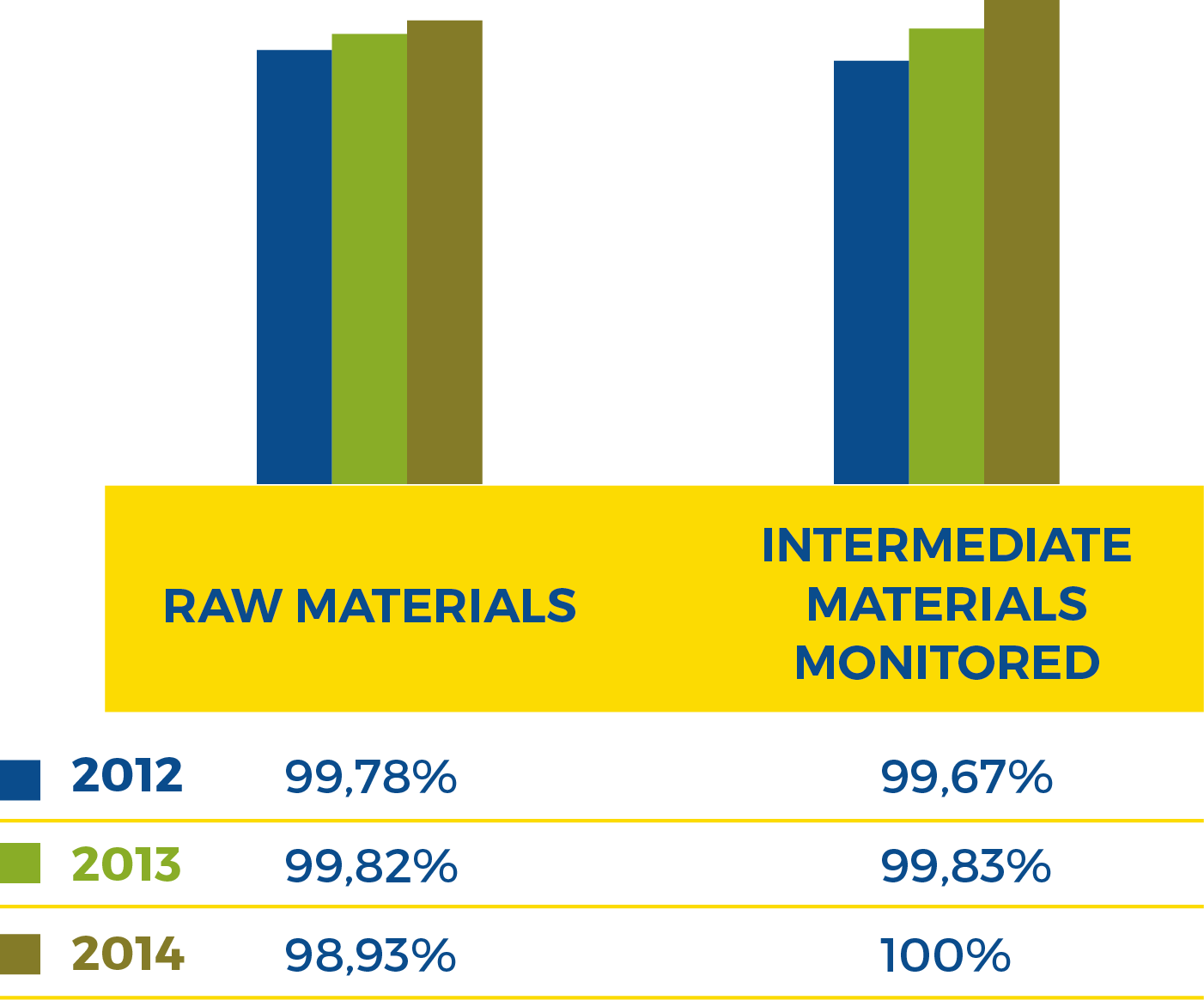

Having good relations with its suppliers is crucial to the success of Termomecanica. That is why the company values the creation of long-lasting partnerships based on mutual commitment, a fundamental aspect for adding value and providing sustainability for the business. The entire process for evaluating, qualifying and monitoring suppliers is undertaken with great care so as to ensure that raw materials and the intermediate materials received, as well as the services rendered, are provided with quality without causing any kind of impact on the environment or risks to personal health and safety. To that end, all suppliers are registered in advance and provide full corporate documentation updated by government bodies, as well as other documents required for their validation. To ensure the efficiency and agility of the process, Termomecanica employs an internal supplier management system that is managed through the corporate portal, based on technical and legal criteria, by type of segment of the material or service to be provided. The requirements of Termomecanica include: ► Strict compliance with the chemical and technical specifications applicable to the product, as the case may be; ► Compliance with the requirements regarding the standards of quality of the product or service supplied; ► Compliance with the international standards and guidelines regarding the use of controlled substances and/or in the manufacture of certain materials acquired (Rohs/Reach); ► Compliance with basic health and safety and environment standards, when applicable.

Monitoring and evaluation

The company also monitors the performance of its suppliers, assessing criteria of quality and compliance with specifications, delivery deadlines, punctuality, the correctness of fiscal documentation and compliance with the applicable legal requirements. All this ensures satisfactory performance indices:

One important aspect is that supply contracts, purchase orders and services agreements contain specific clauses repudiating hard labor, preventing the use of slave or child labor or degrading working conditions. In the case of suppliers of scrap, Termomecanica also has a formal procedure setting out the criteria and the guidelines regarding procurement processes, in accordance with the applicable legislation. To enhance the process the company also makes periodic visits, so as to provide guidance on the most appropriate form of packaging, separation and classification of the scrap, verifying the operations and the facilities used by these suppliers.

RESULTS IN 2014

► Review of the Supplier Management Procedure, with the inclusion of other segments of operations, while expanding the criteria for evaluating and monitoring suppliers of scrap; ► Disclosure of the Code of Ethics and Conduct among suppliers; ► Definition of the terms of the Declaration of Socioenvironmental Responsibility; ► Review of the Policy on the Procurement of Scrap.

KEY TARGETS FOR 2015

► Disclose the Declaration of Socioenvironmental Responsibility and request the declaration of compliance and commitment to the theme; ► Undertake a new review of the criteria for evaluating and monitoring suppliers; ► Implement the Policy for Receiving Materials and Scrap in the case of transformation operations (Target of the Commercial – Sales Area).

Customers: Permanent relationships

The tradition of manufacturing products whose excellence is acknowledged by the market also makes Termomecanica a benchmark for its customers. To cultivate good relationships and permanent partnership, Termomecanica has well-prepared service teams that receive periodic training, primarily in matters involving smelting, taxation and negotiation. This type of initiative is important, since the demands of Termomecanica are defined also based on the requirements of the market compiled primarily by those professionals that attend to the company’s customers. These compilations are done by visits involving prospecting, sales and techniques, or even visits involving services associated with the product, as well as specialist publications and customers’ observations. Another important tool for the customer management system of Termomecanica is the satisfaction survey. Carried out once a year, it evaluates aspects such as overall satisfaction, commercial and technical service, product quality and commercial conditions among others. In case of doubts or complaints, the customer can appeal to several service channels, with registration on the internal system (CSU/SAP) and forwarding to the areas responsible. All complaints are analyzed to determine the causes and identify the best actions to be taken, whether immediately or of a long-term corrective nature. Market surveys are carried out using both outsourced institutes whose evaluations range from market share to the trends per segment served, seeking continuous improvement in responding to customers’ requirements, and internally using primary and secondary sources, such as visit reports, publications and internet searches.

Communication channels

To resolve any type of doubt, Termomecanica has several service channels. In the sales area, this can be done over the telephone, e-mail, the B2B TM Business Portal, and on-site visits to the customer and/or Termomecanica. The TM B2B Business Portal is also worthy of a mention, since it has added a new dimension to customer service, facilitating contact with the customer. Designed to be an electronic purchase and relationship channel, it has afforded customers several online solutions, including: ► On-line purchases; ► Inquiries about orders pending and invoiced; ► Viewing a summarized or detailed statement of raw material (primary and/or scrap); ► Quoting for materials; ► Price quotations in real time; ► Making changes to information on customer records. Using the portal, a quotation can be made or an order placed in a matter of minutes, which ensures a rapid speed of response to the customer’s request and with total transparency. Complaints are also logged by the Corporate Portal, Sales Force and SAP and notified in an integrated manner to those responsible for dealing with the requests. All customer complaints logged are analyzed as to the causes and the corrective actions indicated, so that problems are resolved. It is important to remember that the secrecy and privacy of the information provided by the customers are always respected and supported by the Termomecanica Information Security Policy.

RESULTS IN 2014

► 42% increase in the number of customers using the B2B portal; ► 517 valid complaints were attended to by the customer service channels, with 100% of them resolved; ► 35% increase in conversions of quotations via the B2B Portal B2B into sales.

KEY TARGETS FOR 2015

► Increase of at least 10% in the number of customers using the B2B portal; ► Include new functionalities in the portal, enabling enquiries about payment slips/trade;bills and products not in the portfolio; ► Make available a standard format for quotations or orders; ► Customize how reports are viewed.

Local Community: Bonds that only grow stronger

To establish a strong and solid relationship, keeping communication channels open and engaging in social actions through the Salvador Arena Foundation. The commitment by Termomecanica extends beyond the walls of the company to also impact the communities where it is located. The company’s relationship policy ties in with the purpose set out in the bylaws of its major shareholder, the Salvador Arena Foundation: “to cooperate and make all possible efforts to resolve the problems of education, assistance and protection for those in need, regardless of nationality, race, sex, color, religion or political opinions in general”. As a rule, the public must be treated with loyalty, honesty, seriousness, impartiality, fairness and receptiveness, and any suggestions and criticisms received from the community must be dealt with in the appropriate manner. de.

Salvador Arena Foundation, the supporting entity behind Termomecanica, engages in different initiatives of a social and community nature, benefiting more than 30,000 people every year. There are support programs for projects by not-for-profit non-governmental organizations such as child daycare centers, rest home institutions, charity hospitals, professional training centers and other organisms that promote social development. In addition, programs are also given in training and management development, funding and drawing up of projects for managers and technicians of social entities, while free technical advisory is also provided to institutions that intend to regularize their corporate status. Another important project of Salvador Arena Foundation intended for the community is the Salvador Arena Foundation’s Center for Education (CEFSA), which attends to more than 2,500 students every year with free high-quality teaching using 100% own funds. The structure of the CEFSA is composed of the Termomecanica School, the Termomecanica Technical College and the support structure consisting of the Eng. Salvador Arena Theater, the Bronze TM 23 Olympic Stadium and the Salvador Arena Aquatic Center.

Communication with Social Responsibility

The principles of Social Responsibility pervade the work philosophy and can also be seen in every project of the Corporate Communication area, both in relation to content and format. The Corporate Communication area´s mission is to “create, implement and provide support to social communication processes and actions that enable Termomecanica to maintain its positive and favorable image with its key stakeholders”. As a service provider, the Corporate Communication area assists its customers by providing all the support required for engaging in strategic communication in an ethical and responsible manner. Thus all articles are carefully reviewed so that there is no discriminatory, prejudiced or disrespectful content, including with regard to the competitors. The company also uses communication to educate its stakeholders in the theme of sustainability. The in-house communication projects, for example, strengthen positive commitments thanks to newsletters about citizenship, the environment, respect for the surrounding community, precautions with health and finance, among others. The instruments are also used to bolster the attitudes expected with regard to the Corporate Values and the Code of Ethics and Conduct. Formal communication begins with the senior management, managers and departmental heads and follows the hierarchical line down to the employees, also abiding by these basic assumptions.

Communication with Social Responsibility

Termomecanica uses different vehicles to disclose internal information, such as: ► Mural Newsletter: Publishes up-to-date information every week on issues involving citizenship, health, human resources, quality, culture and leisure, among others. It is also used for urgent notifications; ► The in-house newspaper “Somos TM” (We are TM): Launched in 2006, this bimonthly vehicle focuses on employees and their families; ► Corporate Portal: Contains the same information as the Mural Newsletter, as well as digital versions of the “Somos TM” newspaper; ► An 8-page notice board: Updated twice a week, it allows the publication of messages in mosaic format in a clear, direct and visually attractive manner; ► Communication agents: Help to pass on information, clarifying doubts and providing support for critical communication points. They are employees committed to the company and considered to be opinion formers. Also responsible for communication actions with the market, the area employs the key press office tools, advertisements in specialist magazines as well as fairs and events. In 2014, Termomecanica attained the highest ever level of published articles since it began its work in media relations in 2011. The volume was 2.2 times greater than that of 2013 when the company was mentioned in 100 different articles.

RESULTS IN 2014

► Of the 220 articles published, 44% were in media extremely relevant for the business of TM; ► 80 different messages carried in the 8-page notice board; ► Publication of 18 advertisements in 10 different printed media.

KEY TARGETS FOR 2015

► Continue with the project for implementing social responsibility in the company; ► Intensify, through the press office, the work of disclosing the brand to the market; ► Institute routine disclosure of the issues in the campaign “Cobre Essencial à Vida” (Copper – essential for Life) in order to promote the importance of copper for the company, which will be a joint venture with the Procobre (an institute that promotes the use of copper).

Credits

Organization: termomecanica são paulo s.a. Corporate Social Responsibility Area: Maria Luzia de Almeida, Barbara Laura Barbieri Pires, Roselaine A. A. Dantas e Pâmella C. Barcellos Soares. Graphic project and layout: cabrillano comunicação Editing: arlete prieto - textos & cia. Translation: JUST TRADUÇÕES S/S Ltda.